- Home

- About Us

-

Products

-

Water Treatment Equipment

- Capacity 10m3/h Secondary Reverse Osmosis Water Treatment Equipment

- Capacity 1m3/h Reverse Osmosis Equipment

- Capacity 3m3/h Secondary Reverse Osmosis Equipment

- Capacity 8m3/h Secondary Reverse Osmosis Water Treatment Equipment

- Capacity 4m3/h two stage Reverse Osiosis equipment

- Capacity 3m3/h two stage Reverse Osiosis equipment

- Capacity 2m3/h two stage Reverse Osiosis equipment

- Capacity 5m3/h Reverse Osiosis equipment

- Mineral water trea tment equipment of 1-100 ton/hour

- simple water treatment system

- KMR-RO integrated purified water producing unit

- Capacity 3m3/h Reverse Osiosis equipment

- Capacity 2m3/h Reverse Osiosis equipment

- Capacity 2m3/h Reverse Osiosis equipment

- Capacity 1m3/h all-in –one Reverse Osiosis pure water machine

- Capacity 3m3/h two stage Reverse Osiosis equipment

- Capacity 1m3/h two stage Reverse Osiosis equipment

- Capacity 0.5m3/h two stage Reverse Osiosis pure water equipment

- Capacity 10m3/h Reverse Osiosis equipment

- Capacity 10m3/h Reverse Osiosis equipment

- Capacity 6m3/h one Reverse Osiosis equipment

- Capacity 36m3/h one stage Reverse Osiosis equipment

- Capacity 40m3/h one stage Reverse Osmosis equipment

- Capacity 1m3/h one stage Reverse Osmosis equipment

- Capacity 0.25m3/h pure water machine

- Capacity 0.5m3/h intergrated water pureifying machine

- WTUF-20m3/h Utrafiltration equipment

- WTUF-18m3/h Utrafiltration equipment

- WTUF-20m3/h Utrafiltration equipment

- Capacity 1.5m3/h Utrafiltration equipment

- Capacity 3m3/h Utrafiltration heat source removed machine

- Capacity 6m3/h Utrafiltration equipment

- Capacity 2m3/h Utrafiltration equipment

- Capacity 5m3/h Utrafiltration equipment

- WTUF Capacity 5m3/h hollow Utrafiltration equipment material of stainless steel

- WTUF Capacity 5m3/h hollow Utrafiltration equipment

-

Tri-Block Washing Filling Capping Machine

- drinking water production line

- glass bottle washing filling capping machine for wine liquor

- fruit juice production line

- Technological progress for filling production line

- Technological progress for filling production line

- Technological progress for filling production line

- Washing,Filling and Capping Production Line For Pure Water,Mineral Water,Fruit Juice,Spirit,Etc

- XGF Series Washing,Filling And Capping Three-In-One Unit

- Minernal water production line technical process

- Pure water production line technical process

- Fruit juic tea production line technical process

- Tea production line technical process

- Pure/Mineral Water Monoblock Filling Line

- Monoblock Filling and Capping machine for Mineral Water

- Pure/Mineral Water Production Line

- Monoblock Washing Filling and Capping machine for Mineral Water XGF12-12-5

- Monoblock Washing Filling and Capping machine for Mineral Water XGF18-18-6

- Monoblock Washing Filling and Capping machine for Mineral Water XGF24-24-8

- Monoblock Washing Filling and Capping machine for Mineral Water XGF32-32-10

- Pure/Mineral Water Production Line

-

Carbonated Drinks Bottling Line

- carbonated drinks filling line

- Carbonated Drinks Washing Filling Capping Production Line DXGF12-12-1

- Carbonated drink production line technical process

- Carbonated Drinks Washing Filling Capping Production Line

- Carbonated Drinks Washing Filling Capping Monoblock Machine

- Carbonated Drinks Filling Machine-- Sem-automatic

- Carbonated Drinks Filling Machine-- Sem-automatic

- Carbonated Drinks Filling Machine-- Sem-automatic

- Carbonated Drinks Washing Filling Capping Monoblock Machine DXGF24-24-8

-

5 Gallon Barreled Water Bottling Line

- full automatic barrel package production line

- QGF barreled drinking water auto washing filling and sealing unit

- 5 Gallon Barreled Drinking Water Washing Filling and Capping Production Line QGF-120

- QGF-200 5 Gallon Barreled Drinking Water Washing Filling and Capping Production Line

- 5 Gallon Barreled Water Filling Line

- QGF Series Full Automatic Barrel Production Line

- 5 Gallon Barreled Water Filling Line

- 5-10 Liter Bottling line

- Liner Filling Machine

- Beverage filling machine

- Liquid filling machine

- Paste filling machine

-

Semi-automatic Filling Machine

- Liquid Filling Machine (horizontal type)

- Double Heads Liquid Filling Machine(horizontal type)

- Machine with Self Suction for Liquid, Viscosity Liquid

- One Head Ointment Filling Machine(horizontal type)

- Double Heads Ointment Filling Machine(horizontal type)

- One Head LiquidFilling Machine(Vertical type)

- GFA Pneumatic Vertical Filling Machine

- TGJ Pedal Filling Machine

- SGJ Manual Filling Machine

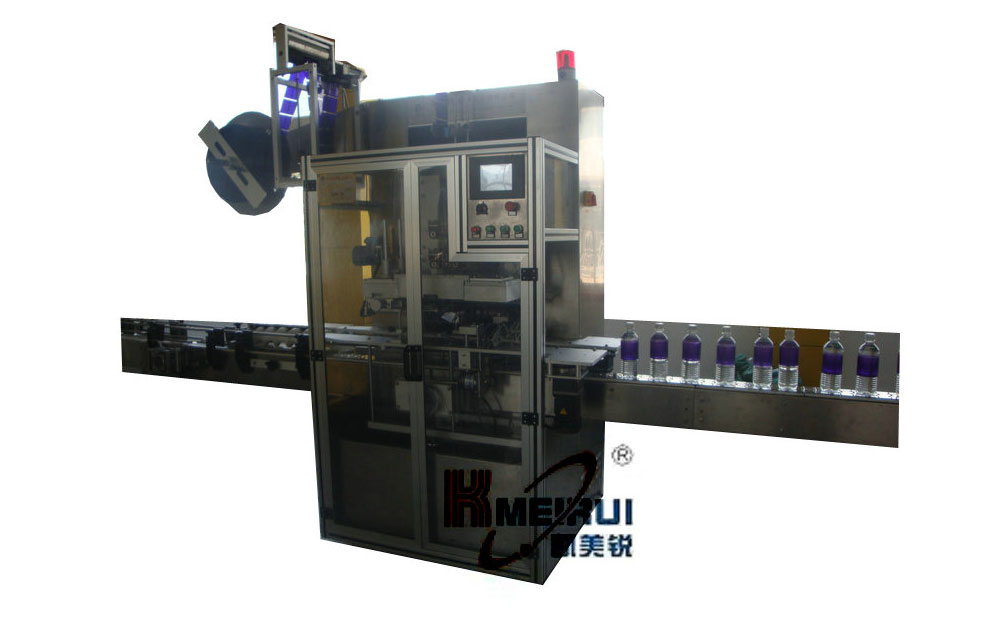

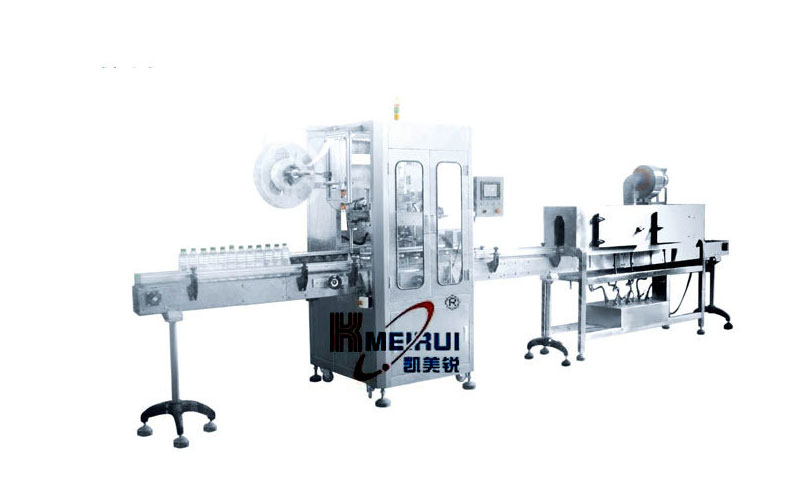

- Sealing and capping, capping equipment

- Labeling, Packaging Equipment

- Automatic Liquid Packing Machine

- Stainless Steel Tank

- sterilizing installation

- filtrating equipment

- The filling machine equipment

- Other ancillary equipment

-

Water Treatment Equipment

- Application

- Video

- NEWs

- Contact Us

English

English