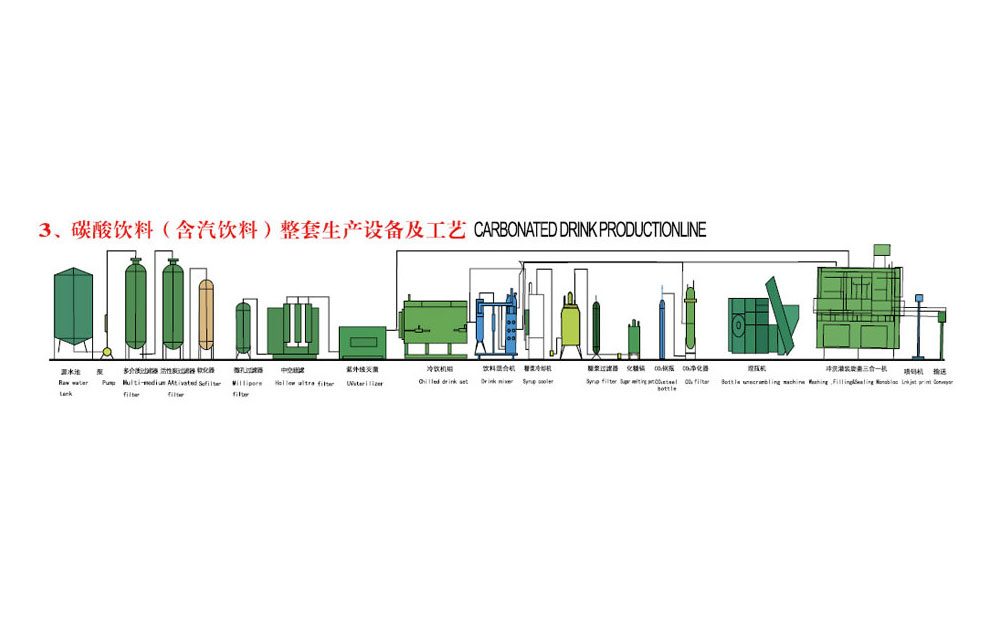

Carbonated beverage filling production line adopts advanced micro gravity filling principle of negative pressure, filling fast, steady, accurate, and is equipped with perfect material flow system, also can realize independent return back to the gas, not contact with the material, reduce the secondary pollution of materials and oxidation.

English

English